Product features:

Fire-proof & non-combustible : A grade fire retardant core material can meet the requirements of fire rating in various space.

High efficiency & energy saving: good insulation performance, low thermal conductivity and low building energy consumption;

Sound insulation: keep good sealing performance and effectively reduce noise interference

High efficiency & energy saving: good insulation performance, low thermal conductivity and low building energy consumption;

Strong and durable: high foaming strength, good mechanical properties;

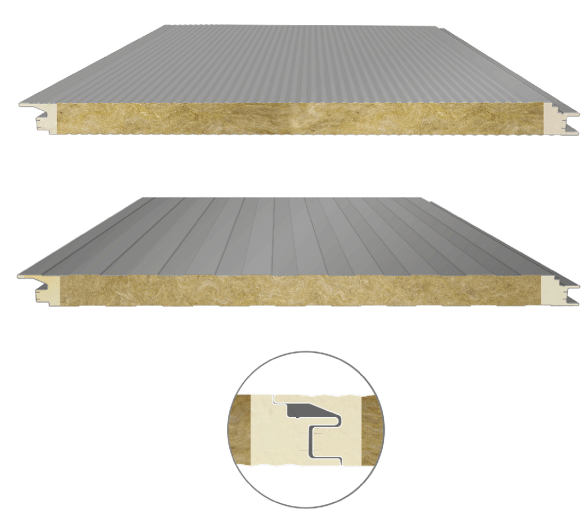

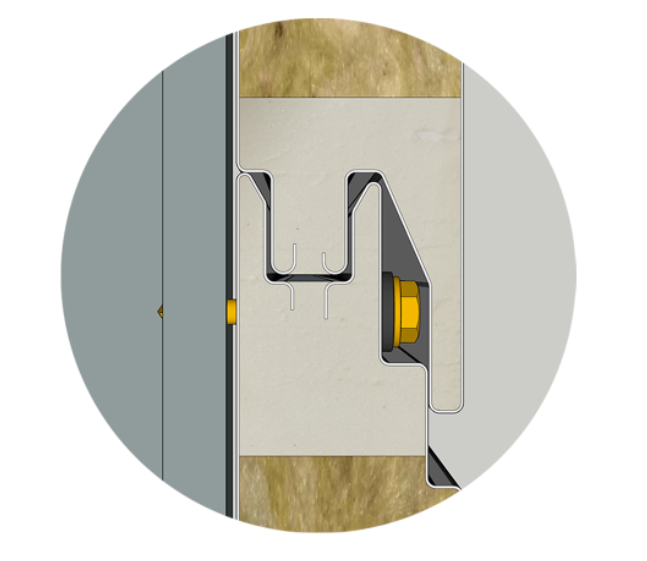

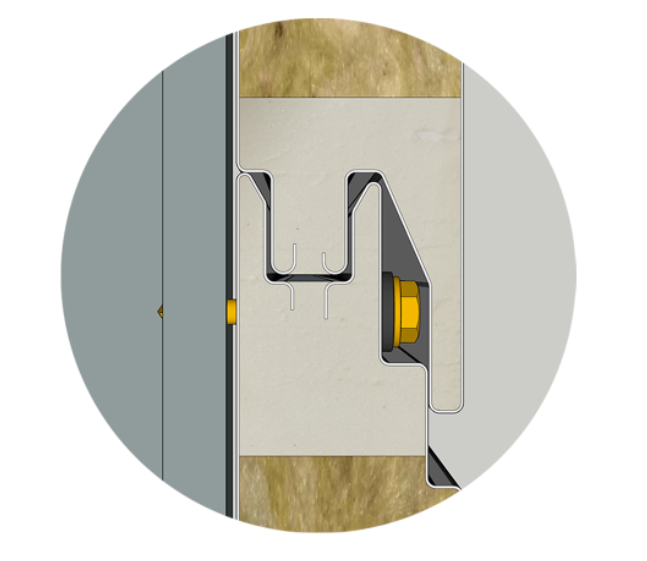

Convenient installation: tongue-and-groove design, realize the integration of assembly.

Beauty & economy: hidden nail connection, beautiful facade, while reducing the cost of traditional construction;

|

SC-PW series |

Parameter |

Surface Form |

Form Sketch |

Thickness |

|

|

Surface material |

Flat |

|

0.4-0.8 |

|

Water ripple |

|

0.4-0.8 |

||

|

Square wave |

|

0.4-0.8 |

||

|

Relief |

|

0.4-0.8 |

||

|

Effective width (mm) |

500/600/700/800/900/1000 |

|||

|

Thickness(mm) |

50/75/100/120/150/200 |

|||

|

Decorative seam(mm) |

Gapless/20/40 |

|||

|

Core material density (kg/m³) |

Rock wool : 100-150 / Glass wool : 64 |

|||

|

Core material selection |

Rock Wool / Glass Wool |

|||

|

Steel plate selection |

Color coaled steel plate , aluminum plate , stainless steel plate , coated steel plate,etc |

|||

|

Color range |

Offwhite , silver gray , sea-blue , crimson and so on |

|||

|

Painting selection |

Polyester coating PE , SMP coating , HDP coating , fluorocarbon coating PVDF , etc |

|||

-

Gapless

-

20mm gap

-

40mm gap

Hidden self tapping screws and various decorative seam design give the wall a beautiful appearance;

Sponge bar embedded design, insulation of air and heat conduction.

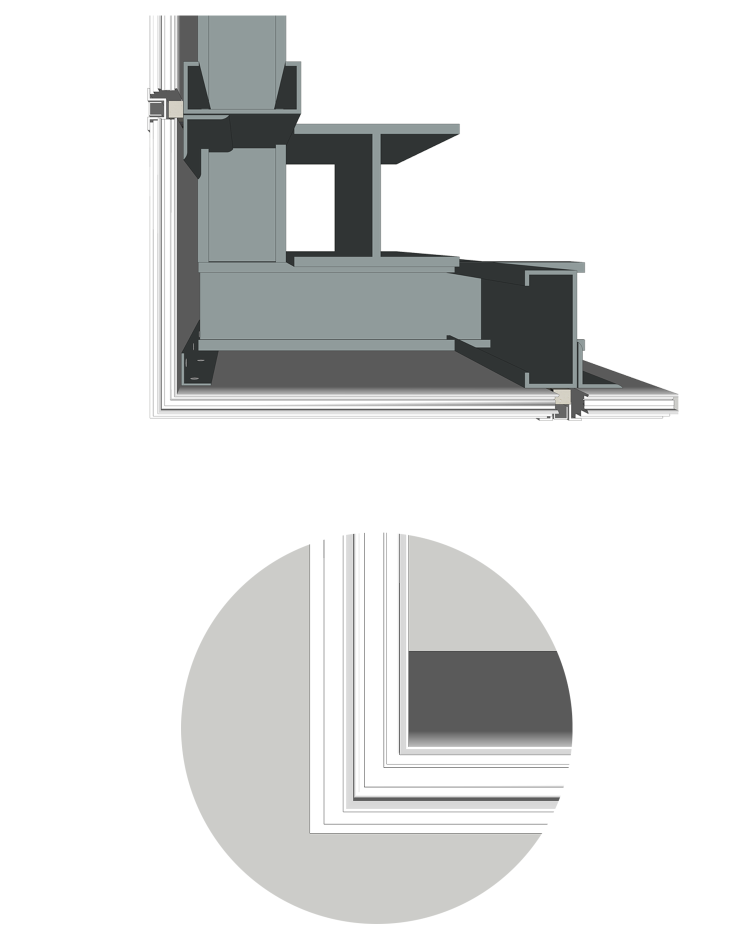

The flashing design under the sill wall can prevent water seepage and wall pollution caused by rain, and ensure the sealing of the wall and the other wall panel; the built-in thermal insulation materials and embedded parts can effectively prevent the cold bridge phenomenon.

The whole split connection of the window and the edge piece realizes the free expansion of the size error between the window edge piece and the wall sandwich panel, which is convenient for the on-site construction, speeds up the installation process, and avoids the trouble caused by the water seepage of the window.

|

Thickness |

Weight |

Load |

60 |

80 |

100 |

120 |

150 |

200 |

Thermal Conductivity |

|

50 |

12.61 |

Two supports |

4291 |

3746 |

3349 |

3042 |

2684 |

2254 |

0.69 |

|

75 |

14.16 |

5711 |

5004 |

4490 |

4091 |

3627 |

3067 |

0.47 |

|

|

100 |

15.71 |

6959 |

6106 |

5486 |

5005 |

4445 |

3770 |

0.36 |

|

|

150 |

17.26 |

9117 |

7999 |

7186 |

6553 |

5823 |

4937 |

0.33 |

|

|

50 |

12.61 |

Multi supports |

4850 |

4195 |

3750 |

3407 |

3006 |

2524 |

0.69 |

|

75 |

14.16 |

6396 |

5604 |

4491 |

4571 |

4062 |

3435 |

0.47 |

|

|

100 |

15.71 |

7794 |

6838 |

6144 |

5605 |

4978 |

4222 |

0.36 |

|

|

150 |

17.26 |

10210 |

8956 |

8048 |

7340 |

6521 |

5529 |

0.33 |

|

|

Note: Steel Sheet 0.5/0.6mm(inner/outer), glass wool unit weight 64kg/m3 |

|||||||||

|

Thickness |

Weight |

Load |

60 |

80 |

100 |

120 |

150 |

200 |

Thermal Conductivity |

|

50 |

15.85 |

Two supports |

4207 |

3655 |

3254 |

2942 |

2581 |

2148 |

0.75 |

|

75 |

18.85 |

5609 |

4984 |

4373 |

3969 |

3500 |

2936 |

0.53 |

|

|

100 |

21.85 |

6840 |

5977 |

5349 |

4862 |

4296 |

3614 |

0.41 |

|

|

150 |

27.85 |

8970 |

7870 |

7036 |

6380 |

5645 |

4763 |

0.31 |

|

|

50 |

15.85 |

Multi supports |

4711 |

4093 |

3644 |

3295 |

2890 |

2405 |

0.75 |

|

75 |

18.85 |

6282 |

5481 |

4897 |

4445 |

3920 |

3288 |

0.53 |

|

|

100 |

21.85 |

7660 |

6694 |

5990 |

5445 |

4811 |

4047 |

0.41 |

|

|

150 |

27.85 |

10050 |

8797 |

7898 |

7180 |

6296 |

5302 |

0.31 |

|

|

Note: Steel Sheet 0.5/0.6mm(inner/outer), RW unit weight 120kg/m3 |

|||||||||